Learn more

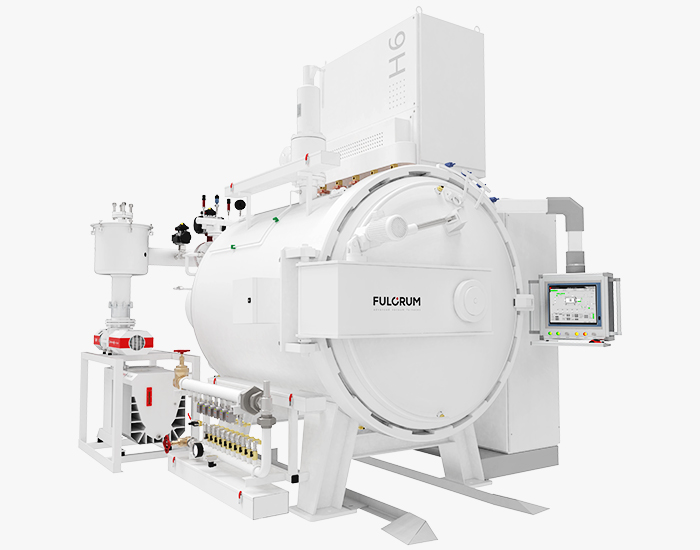

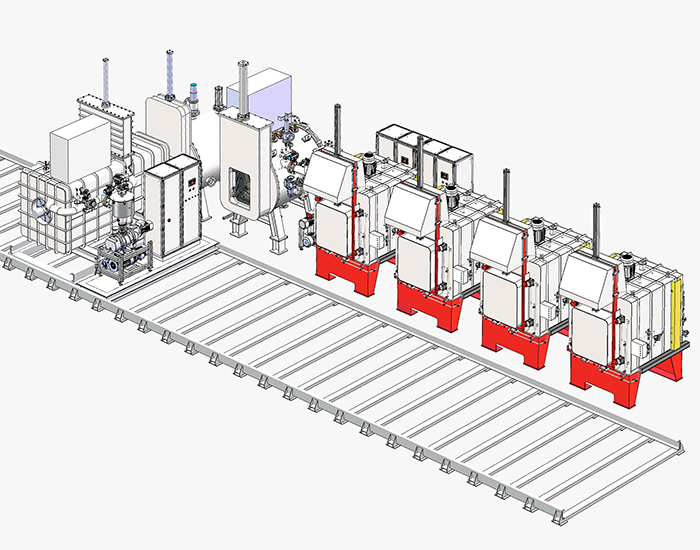

Fulcrum delivers LPC – Low Pressure Carburizing - Automated Line for high performance bearings

Low pressure carburizing - also known as vacuum carburizing- is finding increasing recognition in the heat treatment of high-performance bearings and related components.

Bearing components such as bearing shells, rings (for plain and ball bearings), rollers, etc., and other precision parts require high surface hardness and a tough core.

Today, the automotive and aerospace industries are frequently using LPC-treated bearings due to their enhanced durability and resistance to dynamic loads.

LPC offers a number of relevant advantages, when compared with other processes, as it is characterized by unique features:

- No Intergranular Oxidation (IGO): unlike traditional carburizing, LPC occurs in an oxygen-free vacuum, preventing surface oxidation and ensuring a clean, metallurgically sound structure.

- Uniform Case Hardness: even complex geometries (e.g., deep grooves or blind holes in bearings) receive homogeneous carbon diffusion, critical for consistent performance.

- Environmental Benefits: the amount of process gas used is significantly reduced, when compared for example with atmosphere carburizing (CH4).

Low-pressure carburizing is a proven method for enhancing bearing performance, offering superior hardness, fatigue resistance, and dimensional stability. Its adoption is growing in industries demanding high reliability and minimal post-processing.

For further details, contact Fulcrum specialists, at info@fulcrum-hss.com .