Learn more

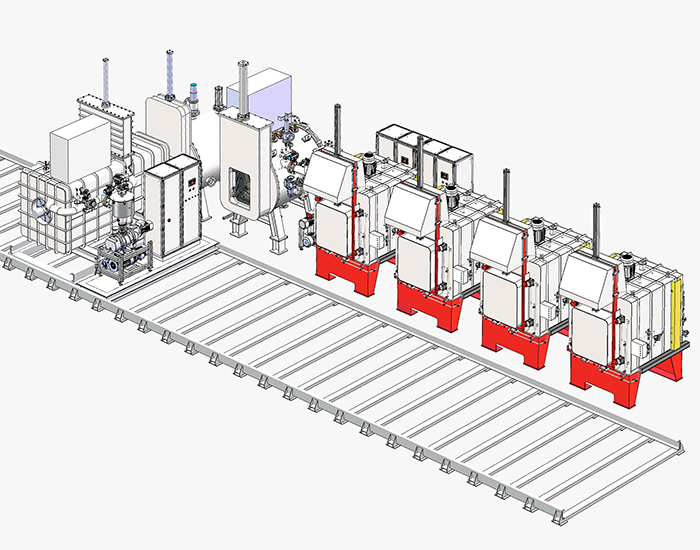

Automated Line

The fully automated heat treatment modular line includes multiple independent vacuum heating and quenching chambers to provide high production capacity and maximum flexibility for a wide range of applications in the automotive and aviation industries.

Automated Vacuum Heat Treatment Modular Line

The fully automated heat treatment modular line includes multiple independent vacuum heating and quenching chambers to provide high production capacity and maximum flexibility for a wide range of applications in the automotive and aviation industries.

The independent modules can simultaneously carry out different thermal and thermochemical treatment processes or be switched off as needed, depending on the production capacity requirements.

Compared to continuous lines, this setup offers increased flexibility and significant energy savings.

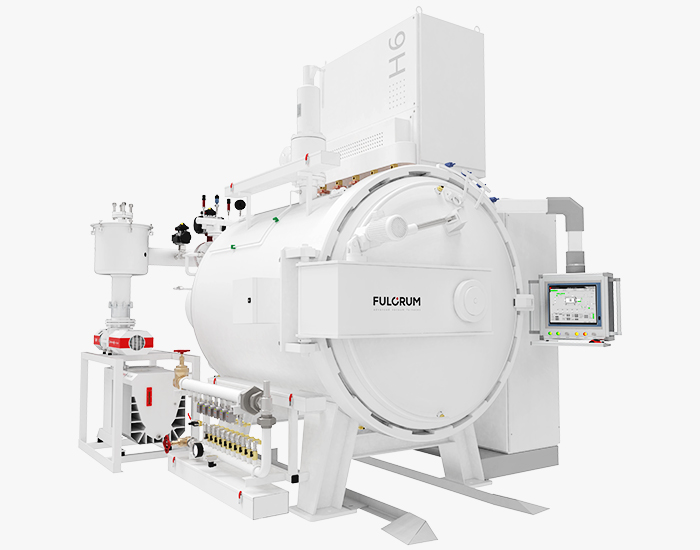

Vacuum heat treatment modules

Thanks to its modular design, the Fulcrum automated heat treatment line can be expanded with additional heating and quenching chambers without halting production. This expansion requires a lower capital investment compared to equivalent lines using independent batch equipment.

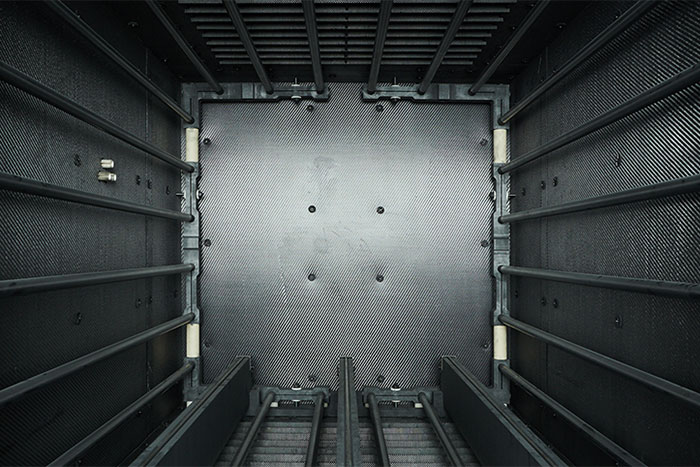

Vacuum heating chamber module

The vacuum heating chamber module provides an oxygen-free environment for thermal and thermochemical processes. It houses a graphite hot zone where the load is heated to the programmed temperature. The vacuum chamber can be equipped with Low Pressure Carburizing (LPC) and Carbonitriding (LPC/CN) process modules.

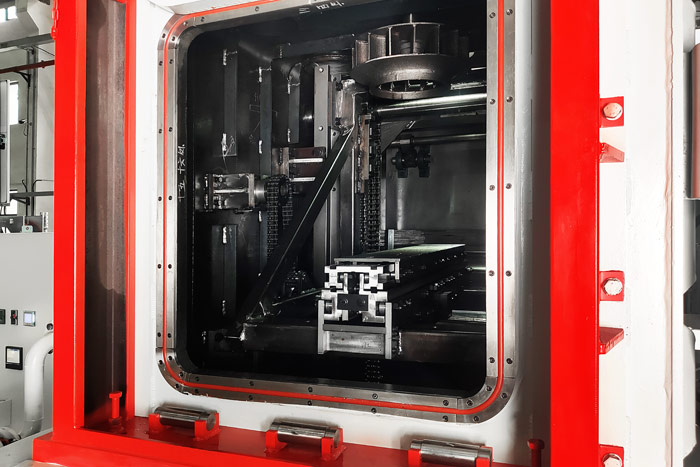

Gas quenching chamber module

In this chamber the load is quenched through the forced circulation of pressurized protective or inert gas. The system is designed to guarantee very high and homogeneous cooling rates, delivering the highest quality in hardening processes. A reversing mechanism allows the cooling direction of the quenching gas flow to be inverted and alternated as needed, depending on the specific load characteristics and application.

Oil quenching chamber module

Within this chamber, the load is lowered into an oil tank, where it is quenched at extremely high cooling rates. A system of agitators regulates the required quenching intensity, ensuring the load achieves the properties suitable for its application. The oil quenching chamber can also be pressurized up to 1.9 bar above atmospheric pressure, with forced circulation of protective or inert gas, facilitated by a centrifugal fan installed at the top of the chamber.

Load shuttle module

The load shuttle module is a vacuum chamber equipped with a heating system that transfers the load between parking/loading positions, hot zone modules, and quenching chambers. Moving on rails, the shuttle ensures rapid and precise transfers. Its operations are fully integrated into the control system, guaranteeing safe operation under all conditions, both during production and maintenance.

Standard dimensions ( W x H x D )

400 x 400 x 600 mm

500 x 500 x 700 mm

600 x 600 x 900 mm

900 x 900 x 1200 mm

Loading Capacity

200 kg

400 kg

600 kg

1500 kg

(Altrenative dimensions and customsolutions available)

Ask for a quote

Leave your contacts and our engineers will call / email you back to help finding the solution you are looking for.

Our privacy policies.