Learn more

Single-Chamber Vacuum Furnaces

Designed for high-performance heat treatment, Fulcrum's single-chamber vacuum furnaces offer consistent heating, advanced gas quenching, and contamination-free processing for the best metallurgical results.

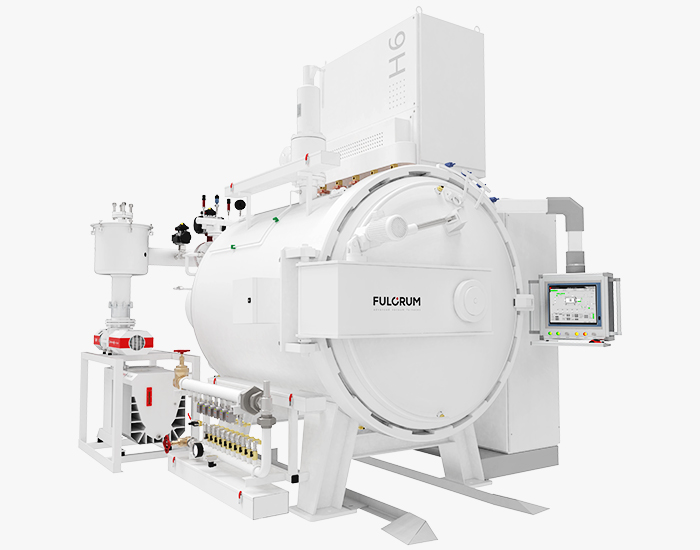

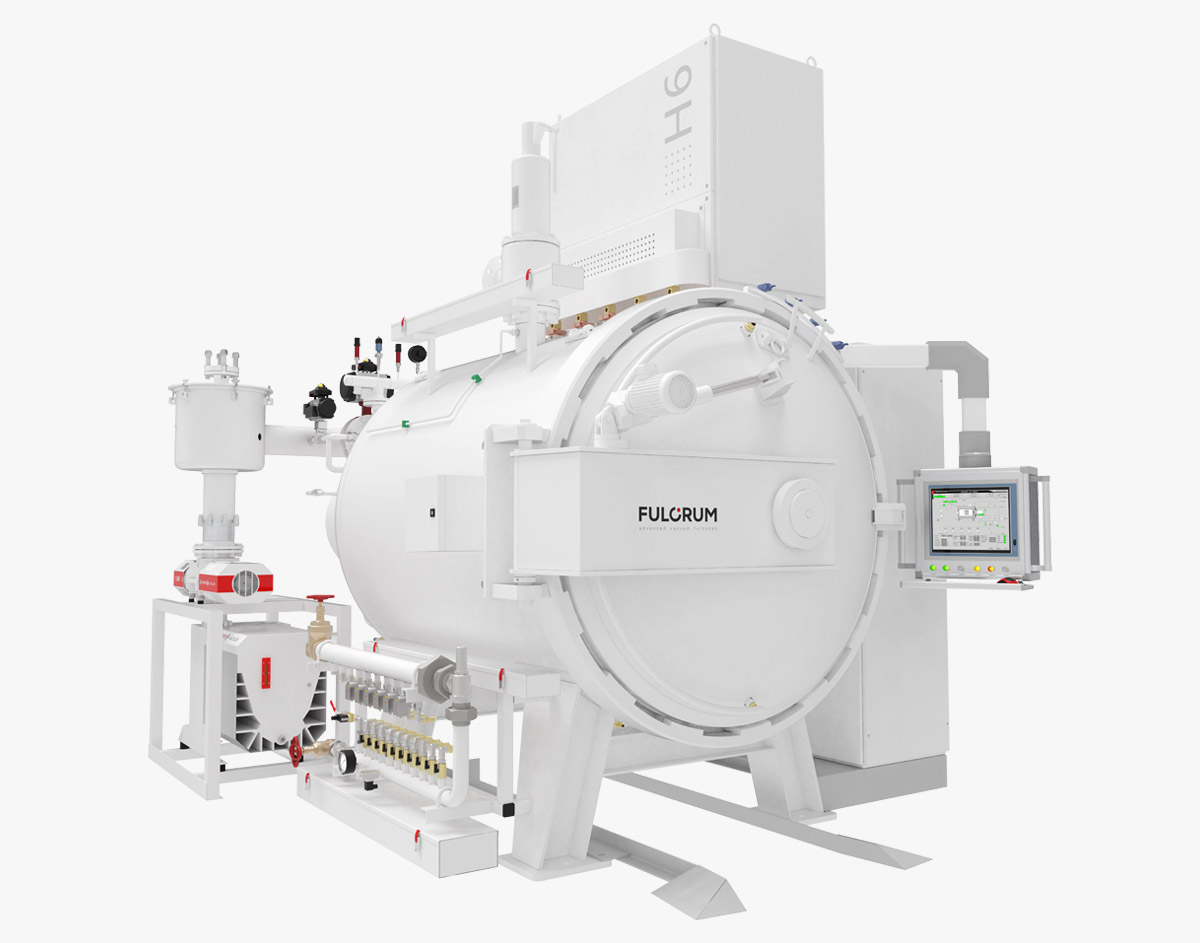

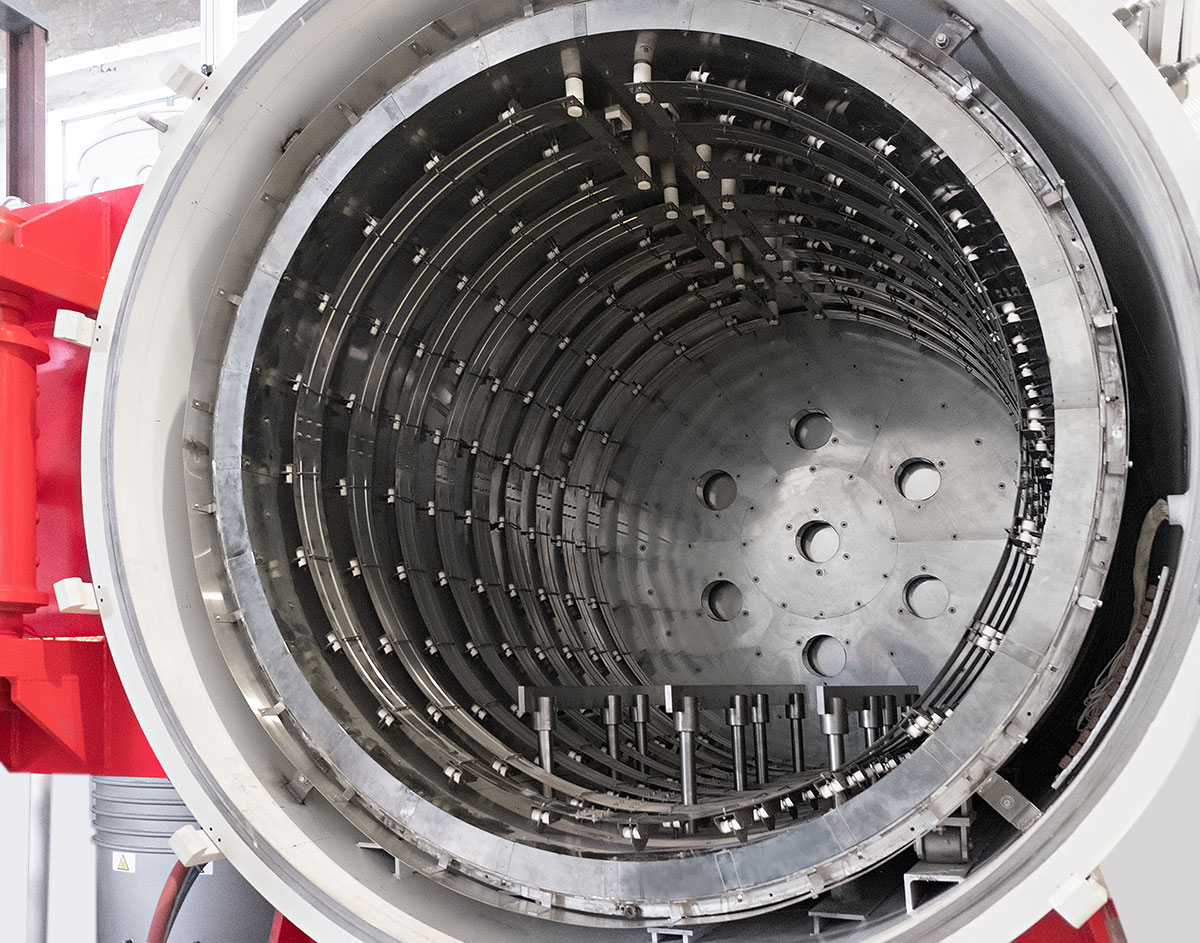

Single-Chamber Horizontal Vacuum Furnaces

Fulcrum horizontal vacuum furnaces ensure heat treatments with molecular precision and reproducible processes for aerospace, automotive, commercial heat treaters and metal processing firms.

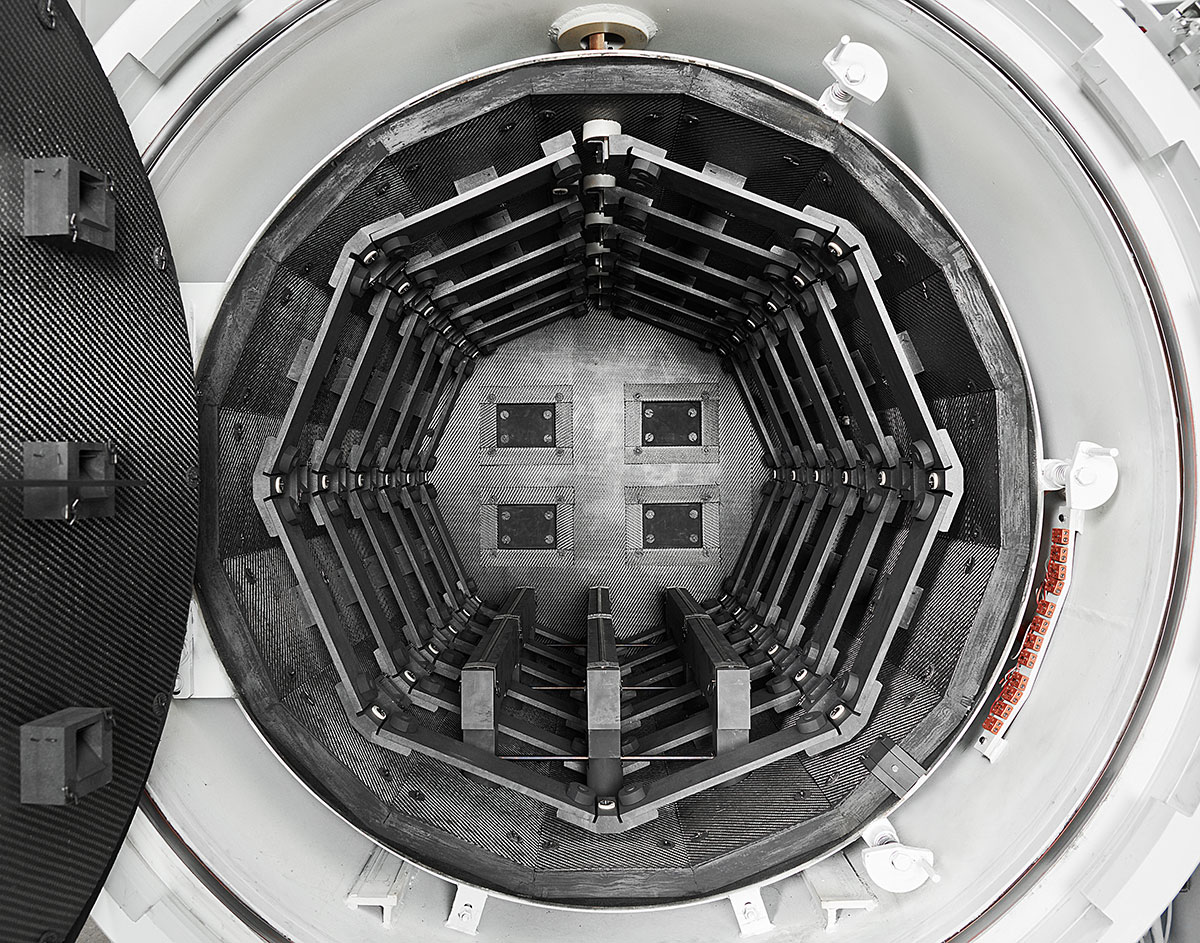

Our cold-wall furnaces can reach extremely high vacuum levels and are available in various sizes and geometries. They are offered in fine or high vacuum configurations while the highly customizable hot zones can be a choice of graphite or all-metal with a circular (f-cyclone™) or square (f-cyclone2™) cross-section.

The convection-assisted heating system ensures uniform temperature distribution within the vacuum furnace and the multi-directional gas quenching system supports pressures up to 25 bar with nitrogen, argon or helium, offering precise control of the cooling rate.

The LPC (Low Pressure Carburizing) technology further improves surface hardness and wear resistance, thus ensuring superior quality results.

Standard dimensions ( W x H x D )

300 x 300 x 500 mm

400 x 400 x 600 mm

600 x 600 x 900 mm

900 x 900 x 1200 mm

1000 x 1000 x 1500 mm

Loading Capacity

200kg - 14000kg

Features Options

High vacuum system

LPC - Low pressure carburizing

(Altrenative dimensions and customsolutions available)

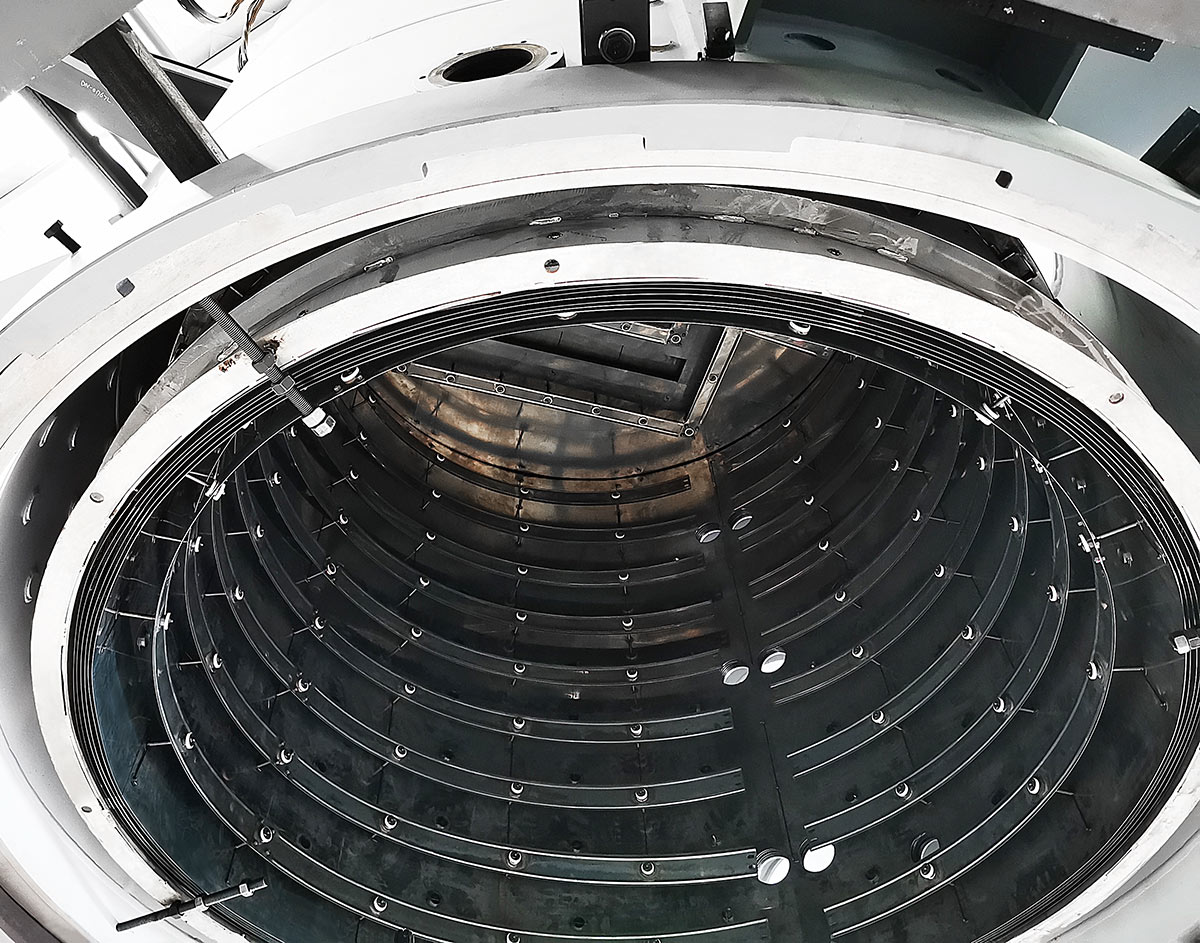

Single-Chamber Vertical Vacuum Furnaces

Fulcrum vertical vacuum furnaces are supplied in top-loading or bottom-loading configurations, allowing for the accommodation of tall, heavy or complex-geometric components while keeping distortions during heat treatments to a minimum.

Supporting several pressures and gases, the advanced gas quenching system guarantees fast and consistent cooling. These small- footprint vacuum furnaces maximize operational effectiveness by seamlessly blending into current manufacturing facilities.

High precision processes with the most stringent industrial requirements and needing rigorous quality control will find the furnace design perfect as it improves heat treatment repeatability. Reduced cycle times resulting from improved cooling performance increase overall productivity.

By greatly increasing surface hardness and durability, the Low Pressure Carburizing (LPC) technology extends component lifetime and guarantees best performance and dependability.

Standard dimensions ( D x H )

900 x 900 mm

1000 x 1000 mm

1200 x 1200 mm

1500 x 1500 mm

1800 x 1800 mm

2000 x 2000 mm

Loading Capacity

800kg - 4000kg

Features Options

High vacuum system

LPC - Low pressure carburizing

(Altrenative dimensions and customsolutions available)

Vacuum Retort Furnaces

Hot-wall, pre-evacuated retort furnaces provide precise thermal processing for tempering, annealing, nitriding and nitrocarburizing uses. Perfect for companies needing high-consistency heat treatment, they are made to run in a controlled low-oxygen environment and guarantee surface quality and uniform treatment.

Available in various sizes, they are equipped with a vacuum pump that allows pre-evacuation of the retort in order to eliminate unwanted contaminants before the introduction of process gases: this minimizes oxidation ensuring cleaner surfaces and better metallurgical properties of the treated elements.

Fulcrum's vacuum retort furnaces are the ideal solution for high-quality heat treatments which, thanks to shorter cycles, make them the most cost-effective choice for the manufacturing industry: their carefully controlled process conditions result in longer component lifetime, lowering rework and raising the general quality of the result.

Standard dimensions ( W x H x D )

300 x 300 x 500 mm

400 x 400 x 600 mm

600 x 600 x 900 mm

900 x 900 x 1200 mm

1000 x 1000 x 1500 mm

Loading Capacity

300 kg

400 kg

800 kg

1500 kg

4000 kg

(Altrenative dimensions and customsolutions available)

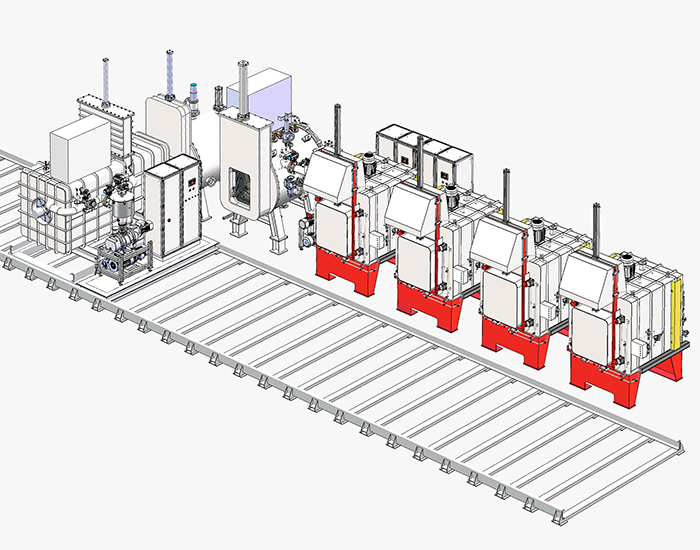

Atmosphere Tempering Furnaces

Atmosphere tempering furnaces are the perfect complement to high-temperature vacuum hardening furnaces, providing oxidation control and improved surface quality in many fine-tolerance manufacturing industries.

Available in a wide range of sizes and suitable for loads up to 10,000 kg, our furnaces offer simplified installations and reduced investment costs.

Though frequently offered as a companion to Fulcrum's vacuum hardening furnaces, these units also function as standalone solutions providing great dependability and simplicity of use. With Fulcrum’s extensive expertise in vacuum heat treatment, customers gain access to a superior approach to atmosphere tempering, backed by advanced engineering and industry-leading technology.

Standard dimensions ( W x H x D )

300 x 300 x 500 mm

400 x 400 x 600 mm

600 x 600 x 900 mm

900 x 900 x 1200 mm

1000 x 1000 x 1500 mm

Loading Capacity

200kg - 10000kg

(Altrenative dimensions and customsolutions available)

Ask for a quote

Leave your contacts and our engineers will call / email you back to help finding the solution you are looking for.

Our privacy policies.