Fulcrum delivers pre-evacuated retort furnace for the heat treatment of precision resistors

Precision resistors are specialized resistors designed to provide extremely accurate and stable resistance values with minimal deviation over time, temperature, and environmental conditions.

They are critical in applications where high accuracy, low drift, and reliability are essential.

Their key characteristics include:

- Low Temperature Coefficient of Resistance, with typical TCR < 50 ppm/°C and < 5 ppm/°C for ultra-precision resistors

- Tight Tolerance, in the range of ±5% or ±1%, and up to ±0.1%, ±0.01%.

- Long-Term Stability, with minimal resistance drift over time in the range of < 0.1% over 10,000 hours.

- Low Noise & Low Thermoelectric Effects.

- Low Voltage Coefficient (for high-voltage applications), with minimum variation of the resistance with applied voltage.

Precision resistors typically use specialized Copper alloys, with Manganese, Nickel and Tin content, and find a wide range of applications in aerospace, automotive, medical, metrology, military and consumer electronics.

A correct heat treatment is essential to stabilize the properties of precision resistors.

The process requires high temperature accuracy and homogeneity within the entire working zone throughout the entire cycle, and it is to be carried out in an oxygen free environment.

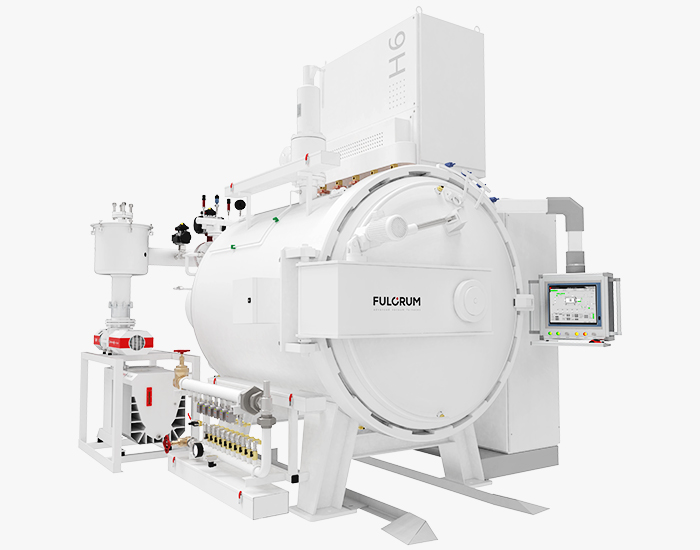

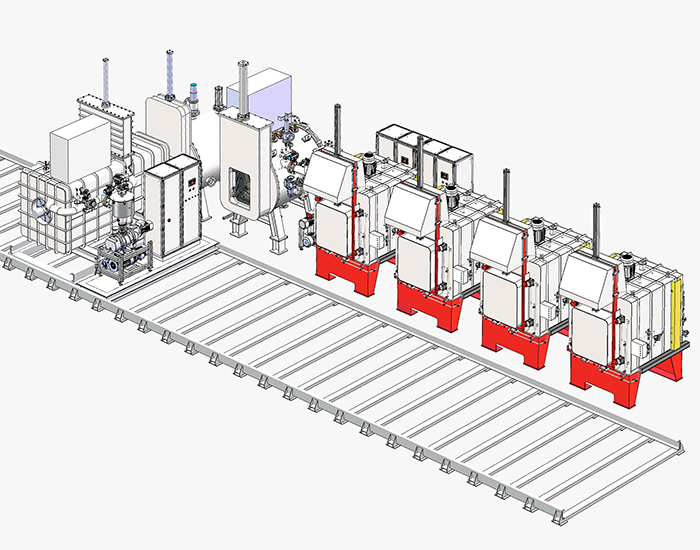

Fulcrum pre-evacuated retort furnaces are state of the art equipment and are the suitable tools for the heat treatment of precision resistors.

Large pumping groups and aerospace grade leak-rates guarantee bright parts, free from oxidation & discoloration.

A sophisticated cascade control interlocked with work thermocouples results in a perfect control of the process parameters and times.

A direct cooling system, complete with inert gas circulation fan and heat exchanger, allows for shorter cycles and increased productivity.